The Challenge

EDR Replacement with Brackish Water Reverse Osmosis Plant

An 80 year old private water utility located in Devonshire, Bermuda set out to upgrade its equipment and infrastructure. Due to the high cost associated with the power required to operate the existing treatment equipment, which was near the end of its useful life, a reliable, fully redundant, high efficiency, high recovery reverse osmosis treatment plant was sought.

The Solution

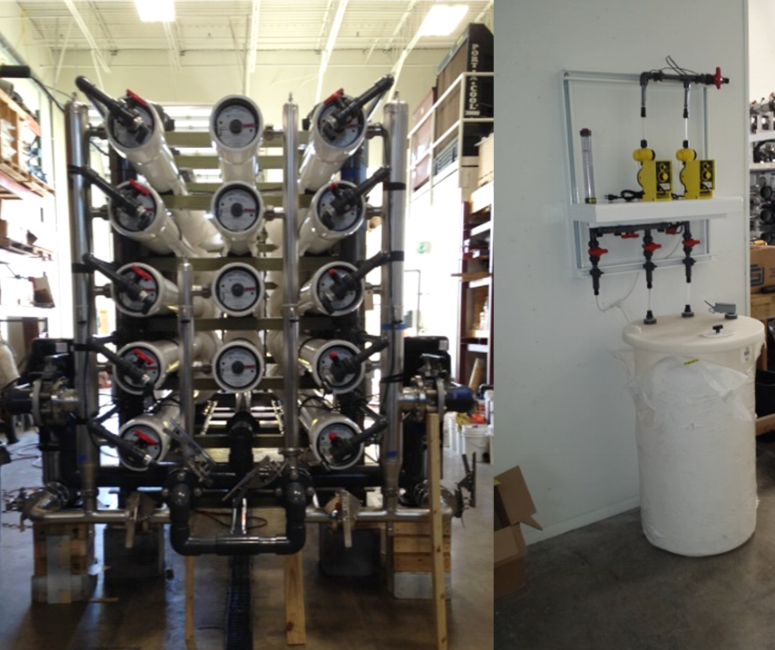

In 2012 Harn was contracted to supply a pilot plant, operated by the utility, to conduct a proof of concept pilot study. In June 2013 Harn R/O Systems was selected to supply the reverseosmosis treatment equipment. Major design points for this system included high feed water recovery, premium efficiency low head boost and high pressure feed pumps, piping designed for minimal head loss, low membrane element flux design, a space saving frame design ‐ where both trains were mirrored on one frame, and supply and installation of a fully integrated plant SCADA system.

The Result

A fully redundant 5:2 ‐ seven element brackish water RO system designed and built by Harn R/O has been in operation since July of 2014. The utility demanded quality materials and a system designed with low O&M costs and ease of operation as a basis of design.

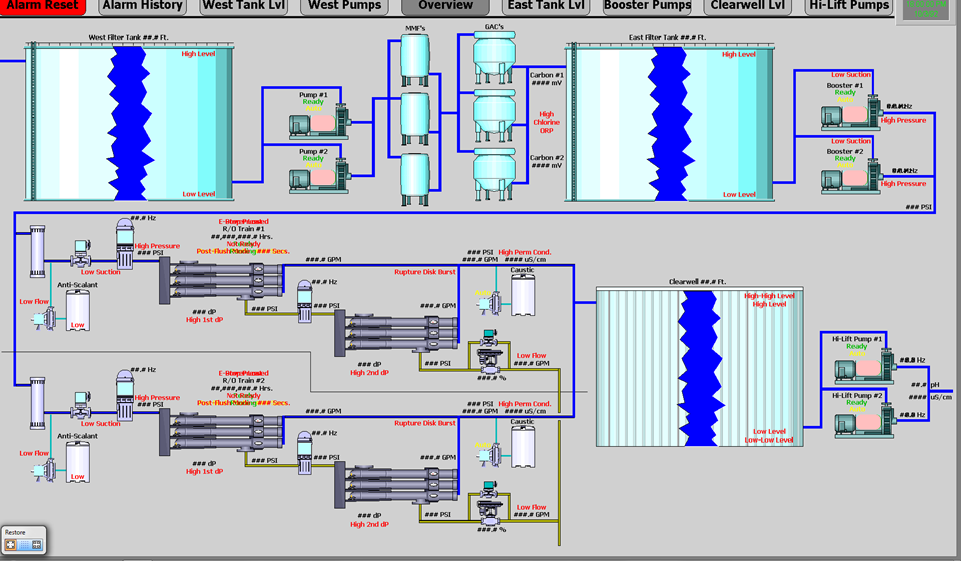

Seawater Treatment Plant SCADA Overview Control Screen

Brief R/O System Specification

| Owner: | Private Utility |

| Application: | Brackish ‘lens’ water |

| Startup: | July 2014 |

| Capacity: | Two (2) 300,000 gallons per day systems at 85% recovery |

| Array: | Two stage 5:2 array; pressure vessels contain 7 elements per vessel |

| Pretreatment: | Clarification, MMF, Scale inhibitor, cartridge filter |

| Low Pressure Piping: | Sch. 80 PVC |

| High Pressure Piping: | 316 Stainless Steel |

| Membrane Type: | Dow XLE 440 |

| Frame Material: | Fiberglass reinforced polymer (pultruded) |

| Operating Data | |

|---|---|

| Feed Conductivity: | 2,974 μS/cm (at start‐up) |

| Feed Temperature: | 74 °F |

| Feed Pressure: | 106 psig |

| SDI: | 3.40 |

| Permeate Conductivity: | 199 μS/cm (93.3% rejection) |

| Permeate Flow: | 173 Imperial gpm (85% recovery) |

| System Features: |

|